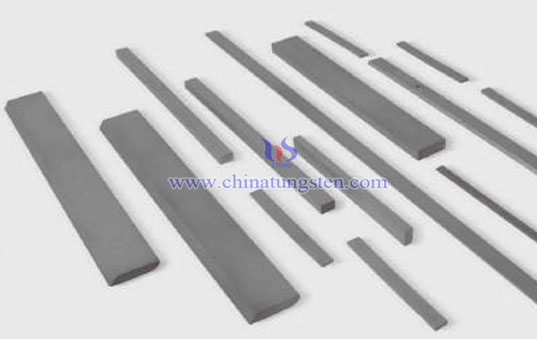

Tungsten Carbide Strip Making Grade

Recommended grade for making tungsten carbide strip and the corresponding application.

Grades |

Equal to |

Density |

TRS |

Hardness |

Applications |

YG7 |

K10 |

14.8 |

1800 |

90.5 |

Better wear resistant than Mk6,used for hard wood used for processing original wood, aluminum section bar, brass rod and cast iron. |

YG6A |

K10 |

14.9 |

1750 |

92 |

Has wear resistance higher than Mk6,used for processing hard wood, original wood, aluminum section bar, brass rod and cast iron. |

YG8 |

K20 |

14.7 |

1900 |

89 |

Wear and percussion resistance, used for processing hard wood, soft wood ferrous and non-ferrous. |

YG8A |

K20 |

14.7 |

2000 |

89.5 |

Wear and percussion resistance, used for processing hard wood, soft wood ferrous and non-ferrous. |

YG10X |

K40 |

14.5 |

2000 |

91 |

Suitable for processing hard wood, veneer board, PCB, PVC& metals |

YG12C |

K40 |

14.3 |

2500 |

87.4 |

For crashing the granite, marble, cobble etc |